Welcome to Hardwood Flooring Costs

Most unfinished domestic species are sold in one of four grades: Clear, with a uniform color; Select, which displays some natural characteristics; #1 Common, which has color variation, streaking, and knots; and #2 Common, with additional color variation and natural marks. #3 Common (also called Utility Grade) is also available, but take into consideration that the lower the grade, the more culling of the wood is involved and there is more filling and sanding before you get to a satisfactory finished product. Only Maple flooring has a different grading system.

Most unfinished domestic species are sold in one of four grades: Clear, with a uniform color; Select, which displays some natural characteristics; #1 Common, which has color variation, streaking, and knots; and #2 Common, with additional color variation and natural marks. #3 Common (also called Utility Grade) is also available, but take into consideration that the lower the grade, the more culling of the wood is involved and there is more filling and sanding before you get to a satisfactory finished product. Only Maple flooring has a different grading system.

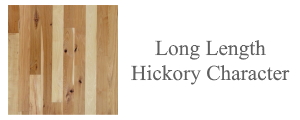

Grading for unfinished hardwoods adheres to standards set by the National Wood Flooring Association (NWFA), but for prefinished hardwoods, terms like "Character" and "Prime" are simply descriptive and vary with manufacturer.

Cabin Grade

Cabin grade hardwoods, however, include both unfinished and prefinished types and significantly cut the cost of wood flooring. Value Grade flooring has some advantages. Priced up to 50% less than standard hardwoods, Value Grade flooring is often $0.89 to $1.19 per square foot. Cabin Grade flooring, also called factory seconds, can be difficult to find, and a distributor's selections vary monthly and depend on the manufacturer's determinations.

Cabin grade is seldom indicative of structural quality and, rather, pertains to the appearance of the hardwood. Factory seconds are characterized by an abundance of dark knots, mineral streaks, and color variation. Physical imperfections may happen in milling, and factory seconds are known to have uneven corners, tree bark edges, or similar features.